3D printing is not a new technology. The technology of 3D printing existed in the 1980s, but the machines at that time were very large and expensive. After more than 20 years of development, the technology has matured and the machines have gradually become smaller. Sales of 3D printers have gradually expanded since the first century, and prices have begun to decline.

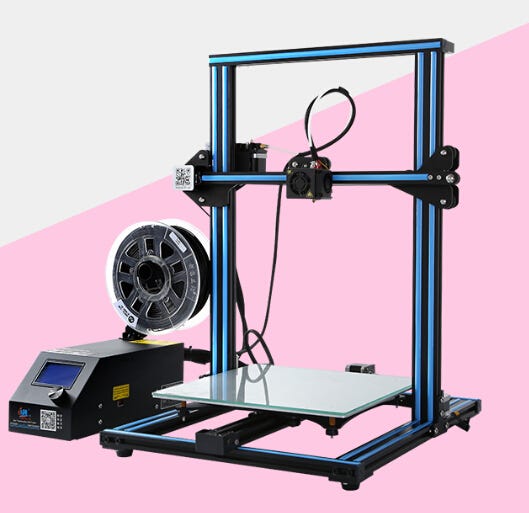

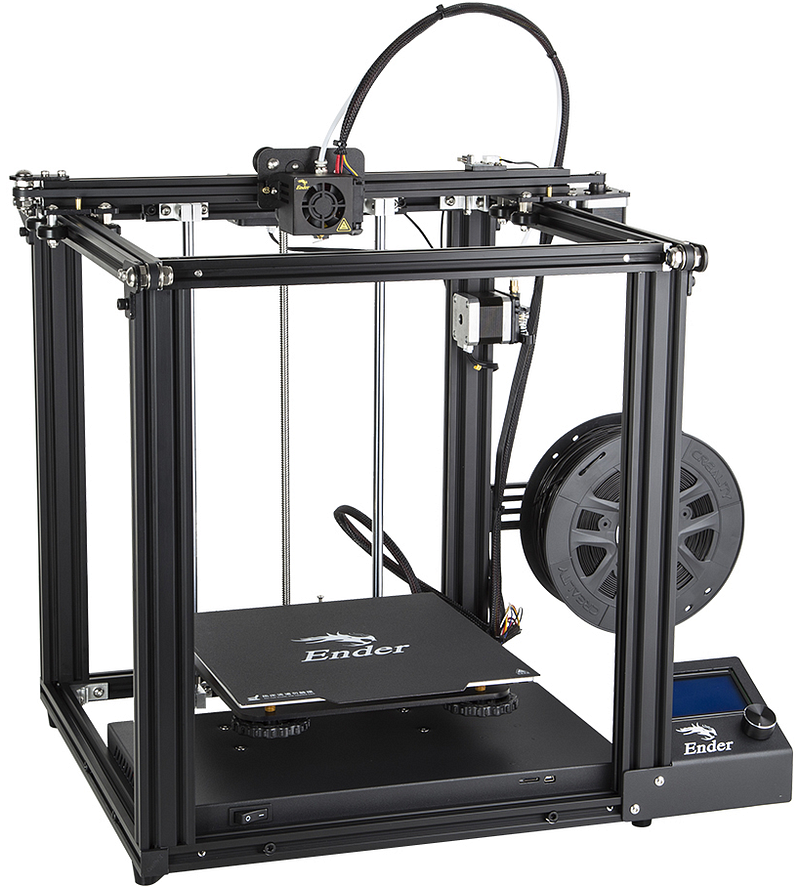

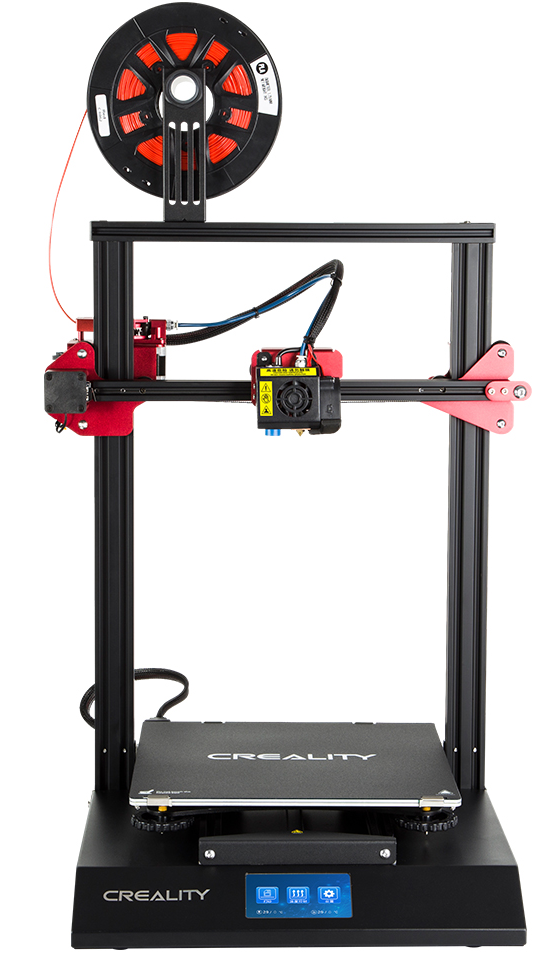

So more and more people are paying attention to 3D printers. The biggest worry for beginners is how to choose a 3D printer suitable for beginners. For curious beginners, 3D printers are too expensive and complicated. Here, we recommend the cost-effective 3D printers of Creality3D, namely Creality3D Ender 3.

What can you do with a 3D printer?

Cheap desktop machines are limited to printing with plastic. If you don’t have a design, you can access the 3D model library like Thingiverse.com to download the design, you can use your imagination. Print out anything from the vase to the phone case. If you’re using CAD software, use a 3D printer to print out whatever you want from your home.

What can you do with a 3D printer?

Cheap desktop machines are limited to printing with plastic. If you don’t have a design, you can access the 3D model library like Thingiverse.com to download the design, you can use your imagination. Print out anything from the vase to the phone case. If you’re using CAD software, use a 3D printer to print out whatever you want from your home.

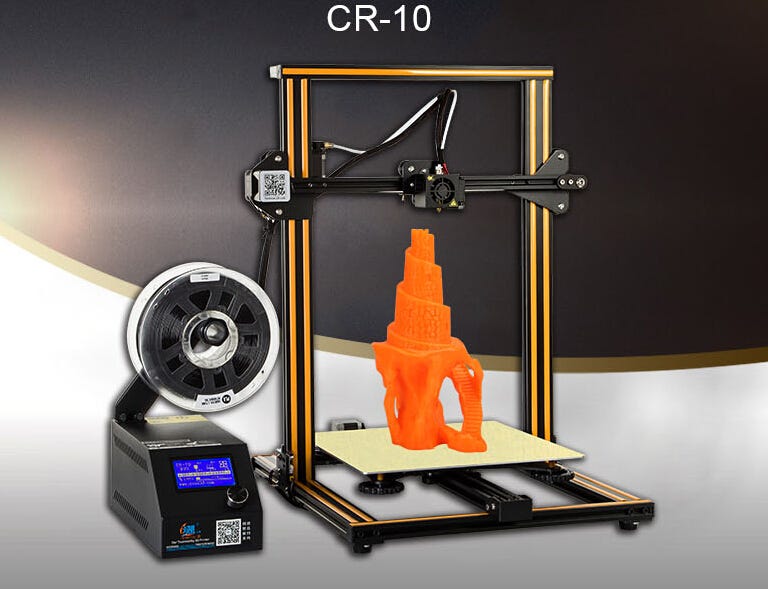

We first select the target machine we are evaluating through people’s online evaluation of word of mouth.

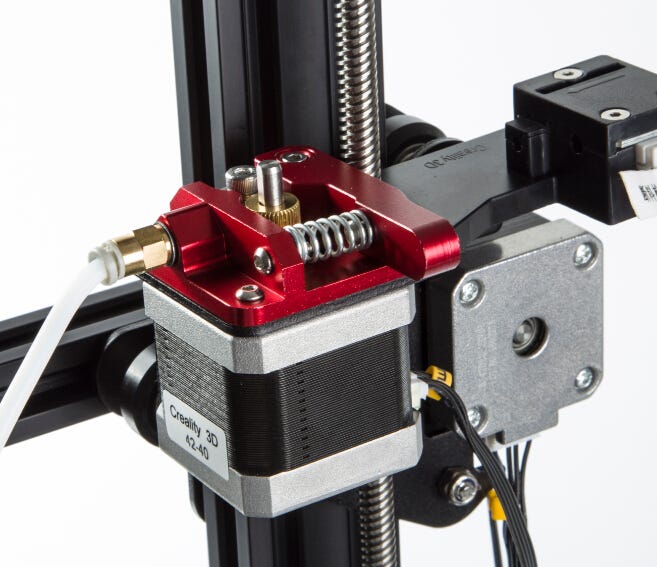

Due to price factors, some advanced 3D printer features have to be sacrificed. But for beginners, these are not too important. After you get started, you can choose a higher-end printer. But the printer’s extended upgrade feature is also a place to watch when evaluating, so if you need more advanced possibilities, you can upgrade your printer instead of buying a brand new one.

Due to price factors, some advanced 3D printer features have to be sacrificed. But for beginners, these are not too important. After you get started, you can choose a higher-end printer. But the printer’s extended upgrade feature is also a place to watch when evaluating, so if you need more advanced possibilities, you can upgrade your printer instead of buying a brand new one.

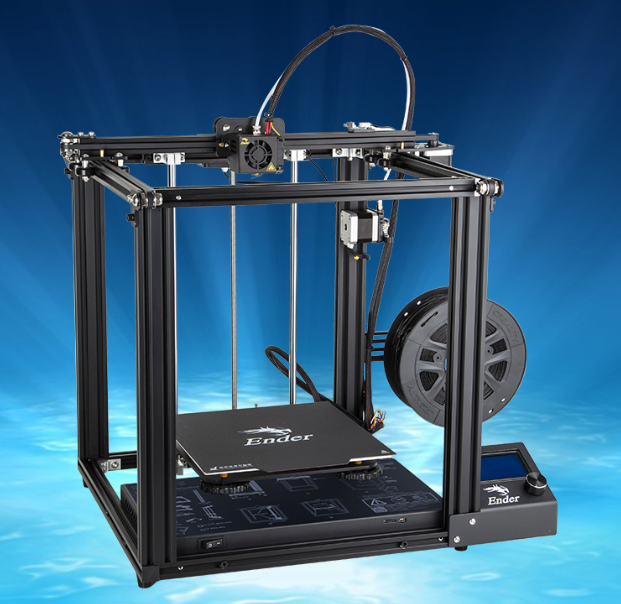

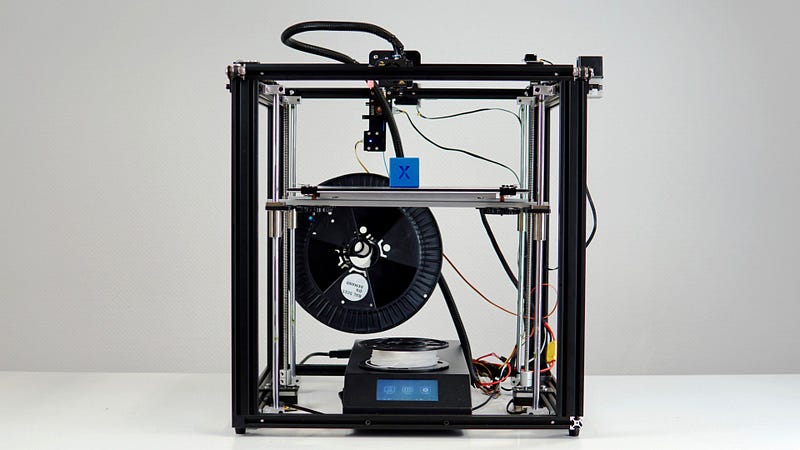

To show the basic functionality of each printer, we printed a few small items and compared the details printed by Creality3D Ender 3. Although Ender 3 provides a lot of setup options to set some fine-tuning during 3D printing, the purpose of this test is for beginners, so we use the default mode of 3D printer for 3D printing.

Ender 3 includes some high-end features that are rare at this price point and can print beautiful models effortlessly. Not only suitable for beginners, but also can meet the needs of some high-end users, even if the cost is higher, but it is value for money.

The Ender 3 is the smartest choice due to its combination of reliability, functionality and design.

The model printed on the 3D printer looks very smooth with only faint visible lines between the layers.

The model printed on the 3D printer looks very smooth with only faint visible lines between the layers.

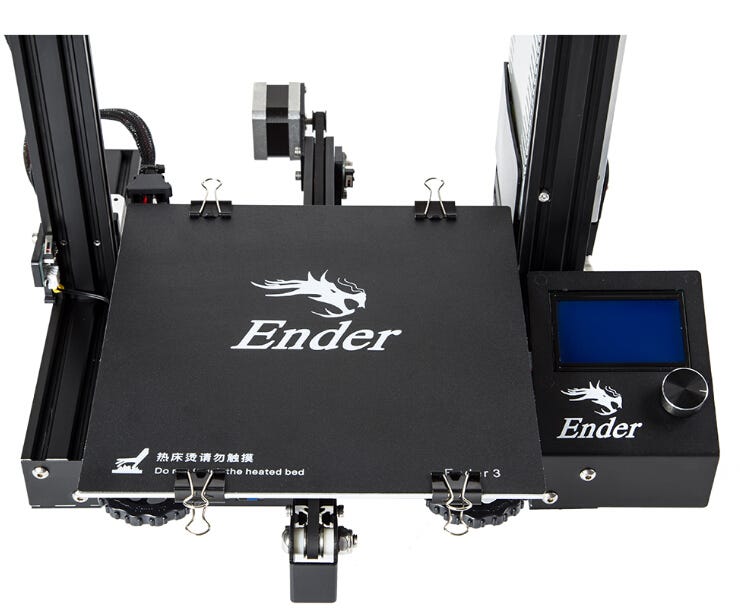

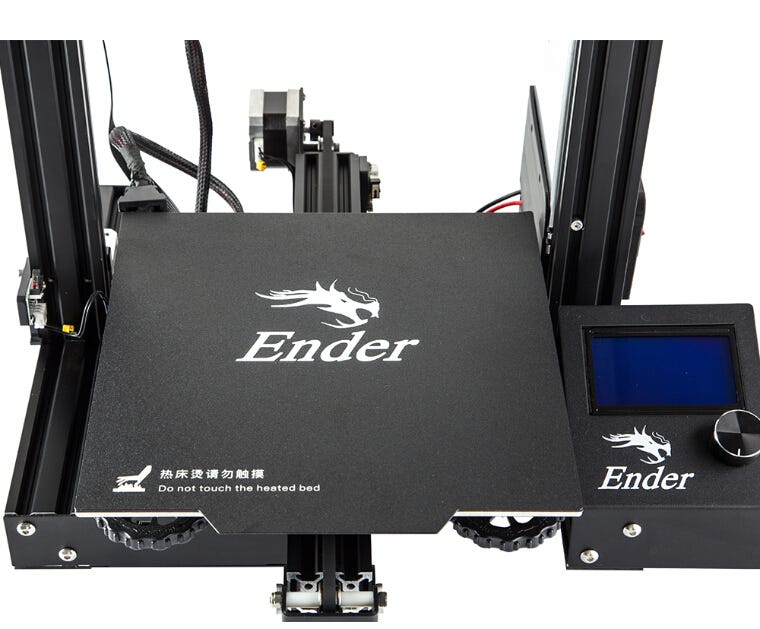

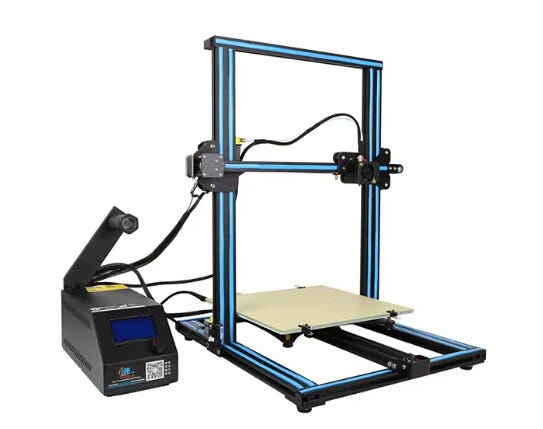

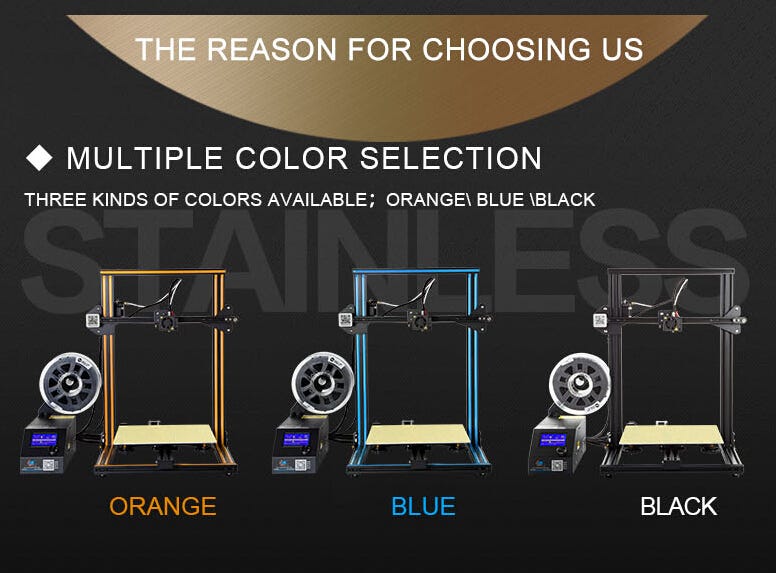

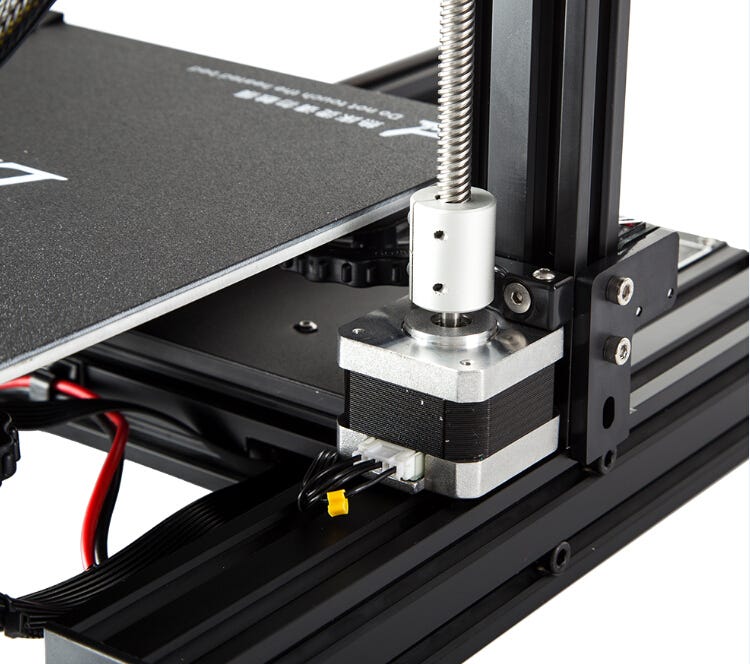

The structure of Ender 3 is relatively simple, it is semi-assembled. We need to assemble it by ourselves when we receive the machine. Of course, this is not very difficult for people who like 3D printing. After all, the manual is written above, then it is printed, Ender 3 There is a control switch next to the electronic screen that allows you to make some settings for the printing process.

The Creality3D Ender 3 can be called a work of art. The open design not only facilitates air circulation, but also has extremely low noise during printing.

Conclusion

3D printers are still in a period of rapid development, and even the most sophisticated printers have various problems. However, when we choose a 3D printer, we should refer to the brand information and product evaluation, so that we can better choose a cost-effective printer.

The Creality3D Ender 3 can be called a work of art. The open design not only facilitates air circulation, but also has extremely low noise during printing.

Conclusion

3D printers are still in a period of rapid development, and even the most sophisticated printers have various problems. However, when we choose a 3D printer, we should refer to the brand information and product evaluation, so that we can better choose a cost-effective printer.

Your email address will not be published.Required fields are marked. *

Originally published at www.3dofficial.com.