Automatic control usually includes:

1、Low temperature and high temperature protection. The printer enters low temperature protection when the printer temperature is too low and the temperature measurement line is shorted. This problem usually occurs when the ambient temperature is below 5 degrees Celsius or the temperature measurement line is disconnected. The maximum temperature of a conventional 3D printer is close to 250 degrees. When the printer temperature exceeds 250 degrees, the machine enters the high temperature abnormal protection mode. It is usually impossible to control machine movement, feeding, printing, etc. after a temperature measurement abnormality occurs in the machine.

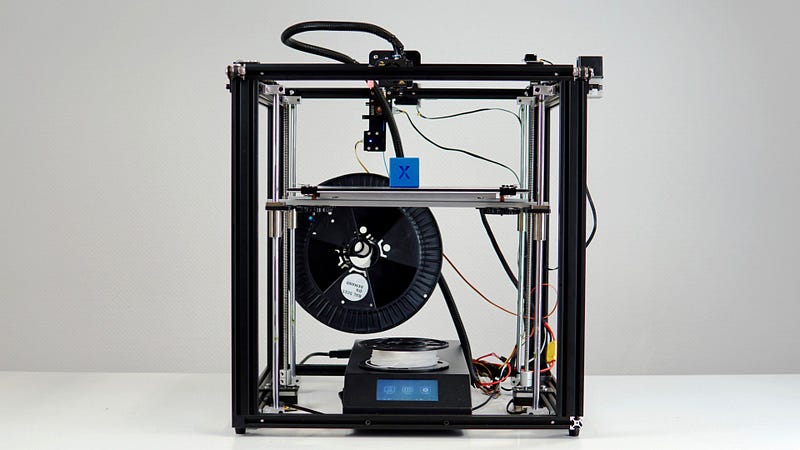

2、Cooling system. Usually the printer includes multiple cooling fans, one power supply fan, one main board fan, one sprinkler fan, and one model fan.

The power supply fan is turned on when the power supply temperature is too high or the power output power is large.

The main board fan dissipates heat from the heating functions on the main board. Usually, the main board heating function includes a motor drive to control the heated mos tube, so the fan will automatically open when the printer has motor rotation or heating.

The nozzle fan dissipates heat from the nozzle. The nozzle usually needs to be heated to more than 200 degrees when printing. If there is no good heat dissipation nozzle, the heat will be transmitted to the upper throat and the motor, causing the overheating to affect the print head. The nozzle fan is usually heated at the nozzle. Automatically open when the nozzle temperature reaches a certain temperature.

The model fan usually dissipates heat from the model. If the nozzle is not cool well after the nozzle is extruded, the suspension may collapse. The printing process usually starts when the fan is turned on. The fan switch usually has a layered software Setting.

The layering is essentially to convert the model into corresponding heating, switch the fan, and move the command from one point to another, and then the machine executes the commands by reading the card And so on.

Common problem:

Q: After the print is clicked, the temperature of the nozzle gradually decreases?

A: Since the printer printing process is the process of executing the print file one by one command, the command to start printing is usually heating the hot bed, heating the nozzle, returning to zero, etc. The heating process needs to wait for the temperature to reach the set temperature value before executing the next instruction. Therefore, when the hot bed is heated and the temperature of the hot bed does not reach the set temperature, the command to heat the nozzle is not executed, and the nozzle that is heated if there is no nozzle heating after the nozzle temperature is raised by the preheating method or the like does not heat up. And the nozzle temperature will gradually decrease due to heat dissipation.

Q: How do you see if the model prints normally during printing?

A: The first time of bonding is usually observed when printing. If there is any situation where the leveling is too tight or the bonding is not possible or the material is not discharged, if there is any problem with the leveling, stop the re-leveling in time. When the bottom layer prints normally, you can occasionally observe whether there is any warping or unloading during the printing process. The warping edge can be re-leveled, the hot bed temperature is increased appropriately, and the layering is modified to add a wider skirt and a bottom mesh. solve.

Q: Do I need to look at the printer all the time under normal printing?

A: No, it will automatically stop, cool, etc. after the machine is finished printing.

Q: Why is the higher the accuracy of the model printing?

A: When printing on some slender columns, sticks, etc., if the model is printed vertically, the higher the print, the larger the sway of the model, which will cause the model printing process to sway, resulting in misalignment, faults, etc. An inclined support rod can be added at a certain height to ensure that there is no sway at the top of the model.

没有评论:

发表评论